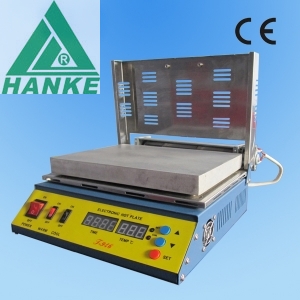

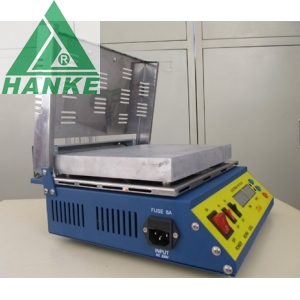

Pre-heating Plate

Home > Micro-computer Hot Plate > Pre-heating Plate

Product Name:

Pre-heating PlateModel No.:

HK-T946

Product Abstract:

1. Adopts MCU and advanced PID intelligent temperature control heating technology & advanced temperature measurement technology, make temperature exact. 2. Special temperature correction function, it can improve the temperature measuring quality and measurement accuracy. 3. Automatic parameter memory function, set and keep parameter easily. 4. Intelligent fault detection function, remove the fault easily, save time and high efficient, ensure the stability and reliability. 5. With time mode and continuous mode in order to meet different user requirements.

- Product Description

- Product Features1. Adopts MCU and advanced PID intelligent temperature control heating technology & advanced temperature measurement technology, make temperature exact.2. Special temperature correction function, it can improve the temperature measuring quality and measurement accuracy.3. Automatic parameter memory function, set and keep parameter easily.4. Intelligent fault detection function, remove the fault easily, save time and high efficient, ensure the stability and reliability.5. With time mode and continuous mode in order to meet different user requirements.6. Adopt imported high quality silicon controlled, with non-contact switch quick response、control precision、without the noise and low power consumption etc.7. With high-quality aluminum, using a integrated techniques combined with excellent machining process produced heating plate, high heating modulus, fast heating, heat even, keep shape at high temperature.8. Heating at bottom, especially suitable for LED industry aluminum base plate lamp bead welding repair, effectively avoid the traditional welding mode of high temperature on light bead damage, significantly extend the service life of bead light.9. Temperature control range can be suit for any electronic industry. Such as lead and lead-free PCB board preheat, welding Repair, sealing compound,Adhesive Dispense constant temperature heating and industrial industries constant temperature heating, sample roasting drying and other temperature test.10. Easy operate,can use machine skillfully after simple training .Main parameterWorking bench size267mm×320mmRated voltage and frequencyAC220-230v/AC110V 60/ 50HzWhole machine power800 WPreheating plate size180mm×240mmPreheating plate temperature range0-450℃Packing listNameQuantityT-946 hot plate11Fuse1User manual11InstructionsThis machine is with two working modes: time mode and continuous mode.1) The timing mode: user set the heating time, it will stop heating when time is up, then it give alarm. The continuous mode: The machine keeps heating unless the user close heating switch by hand.2) Mode setting and conversion: The green indicator light is the working mode status light. The green indicator light is bright if open the machine, press SET , the green indicator light turns off, press SET three times, the green indicator light is bright again, repeatedly operate according to this.The mode selection methodThe green indicator light turn on, open the “WARM” switchThe machine is in the continuous modeThe green indicator light turn off, open the “WARM” switchThe machine is in the time modePress “▲” and “▼” adjust the temperature.The machine need preheat firstly before use it.

1. Basic operation:

1) Check the power line.2) Press”ON”,press “SET”, enter the parameters set interface.3) Set heating time( This time is only effective in timer mode, if the machine is in persist mode, can press “SET” two times, skip the settings)Press “▲”up,“▼”down, adjust minutes to your number(0-99 minutes)Press“SET”, set the seconds, turn seconds to your number(0-59 seconds)4) Set the heating plate working temperatureAfter time setting, press “SET” again; change to temperature setting, the clock digital tube display “FF:FS”, as following:Press “▲”up,“▼”down , adjust temperature to your number(0-450℃)5) Set work mode, start heatingTime mode: Press “SET” several times, until the green indicator light power off, open the preheating switch (WARM), start heating. The red indicator light turn on, digital tube start timing.Continuous mode: Press “SET” several times, until the green indicator light turn on, open the preheating switch (WARM), start heating. The red indicator light turn on, digital tube start timing.6) Stop heatingHeating finished, turn off the heating switch(WARM), the red indicator light power off, the heating plate stop heating(if the machine is in time mode, until the time is up, the machine will stop heating automatically and the digital tube stop timing, the warning buzzer rang two times.)7) Cooling downOpen cooling switch (COOL), cross-flow fan start working, until the temperature of heating plate drop to normal temperature, turn off the cooling switch (COOL).8) Power offTurn off the power switch(POWER),pull off the power line.1) According to the size of the PCB board and welding process requirement, set the machine work mode and heating plate output temperature.2) Open heating switch(WARM), heating plate start working, display temperature rise, until displayed temperature reach setting number, wait for a moment, make the heating plate panel temperature even.3) Put the PCB board on the heating plate, until the solder paste melt, take down the SMD with tweezers or vacuum pen.4) Work finished, take down the PCB board from heating plate, turn off the heating switch (WARM) and the power switch.3. SMD soldering method1) According to the size of the PCB board and welding process requirement, set the machine work mode and heating plate output temperature(Suggest setting in time heating condition, according to the experience setting time, which can effectively prevent PCB overly heating ).2) Open heating switch(WARM), heating plate start working, display temperature rise, until displayed temperature reach setting number, wait for a moment, make the heating plate panel temperature even.3) Put the PCB board on the heating plate.4) The time is up, the heating plate stop heating, check if solder paste is completely melted, if melting is not complete, adjust the timing time, and continue heating. Until solder paste completely melted, take down the PCB board from heating plate. Until solder paste cool and curdle, soldering work finished.5)Turn off and turn on the heating switch(WARM) each time, use the last setting parameters acquiescently, go to the next piece of PCB board soldering.6) All the soldering finished, turn off the heating switch(WARM) and power switch.Caution1. High temperature operation, pay attention to safety, avoid burning.2. Keep heating plate clean, clean with anhydrous alcohol regularly.3. If there are some tin slag on heating plate, clean it in molten state (Don’t use the blade or metal edge tool doctoring, in order to avoid the scratch heating plate).4. If there are some flux on heating plate, turn off the power switch. In normal temperature condition, put some cleanser on heating plate, untilresidue dissolved; use soft cloth to wipe gently. Use soft cloth withanhydrous alcohol wipe the heating plate.5. Long-time no use, should cramp out the power source plug!WarrantyStatementIf any difference between user operating manual and actual product, take actual product as!

- Related Products

- [Return Home] [Print] [Go Back]

Categories

- Lead-free Solering Iron

- Automatic Tin-feeding System

- Lead-free Soldering Tip

- SMT/SMD Rework stations

- Lead-free Soldering Station

- Hot Air Gun/Blower

- Hot Melt Adhesive Gun

- Lead-free Soldering Pot

- Micro-computer Hot Plate

- Fume Absorber and Purifier

- Soldering Accessory

- Electric &Pneumatic Screwdrivers

- Electronic Component Machine

- Microscopes

- Microscope Light

- Magnifying Lamp

- Industrial Camera

- ESD Products

- Cleanroom products

- Industrial tape

- Static control instrument

- BGA Rework Station

- electronic component

Search

Contact Us

Contact Person:

Marketing DepartmentTel:

86-755-36913086 / 28761680Fax:

86-755-33616323Email:

marketing@hksolder.com-